How predictive maintenance extends equipment uptime in modern manufacturing

Predictive maintenance combines sensor data, analytics and operational context to forecast equipment issues before they cause downtime. In manufacturing environments this approach links IoT telemetry, machine models and condition monitoring to improve availability, help procurement plan for spare parts, and support sustainability and supply chain resilience.

Predictive maintenance uses continuous monitoring and analytics to move factories away from reactive repairs toward scheduled, data-driven interventions. By tracking vibration, temperature, acoustic and operational signals, predictive models identify abnormal trends and estimate remaining useful life for components. This allows maintenance teams to plan repairs during low-impact windows, avoid emergency downtime and keep production lines running more predictably while aligning with procurement and spare-parts strategies.

How does predictive maintenance use IoT?

IoT devices are the sensory layer for predictive maintenance, streaming telemetry from motors, conveyors, pumps and control equipment to local or cloud platforms. Edge computing often preprocesses this data to filter noise and reduce latency, while centralized analytics combine historical and real-time feeds. Effective IoT implementations standardize data formats, ensure time synchronization and provide reliable connectivity so models can detect subtle drifts that precede failure. Accurate, timely telemetry is essential to convert sensor readings into actionable maintenance alerts and to improve equipment uptime across production lines.

How does automation improve uptime?

Automation connects predictive insights to operational control so interventions can be coordinated with minimal disruption. When a model signals increased failure risk, automated systems can reduce load, switch to alternate equipment or initiate safe shutdown sequences to prevent catastrophic damage. Integration with production orchestration allows maintenance windows to be scheduled alongside planned downtime or shift changes, reducing lost output. This close coupling between analytics and control shortens response times, lowers the chance of cascading failures and helps maintain consistent throughput.

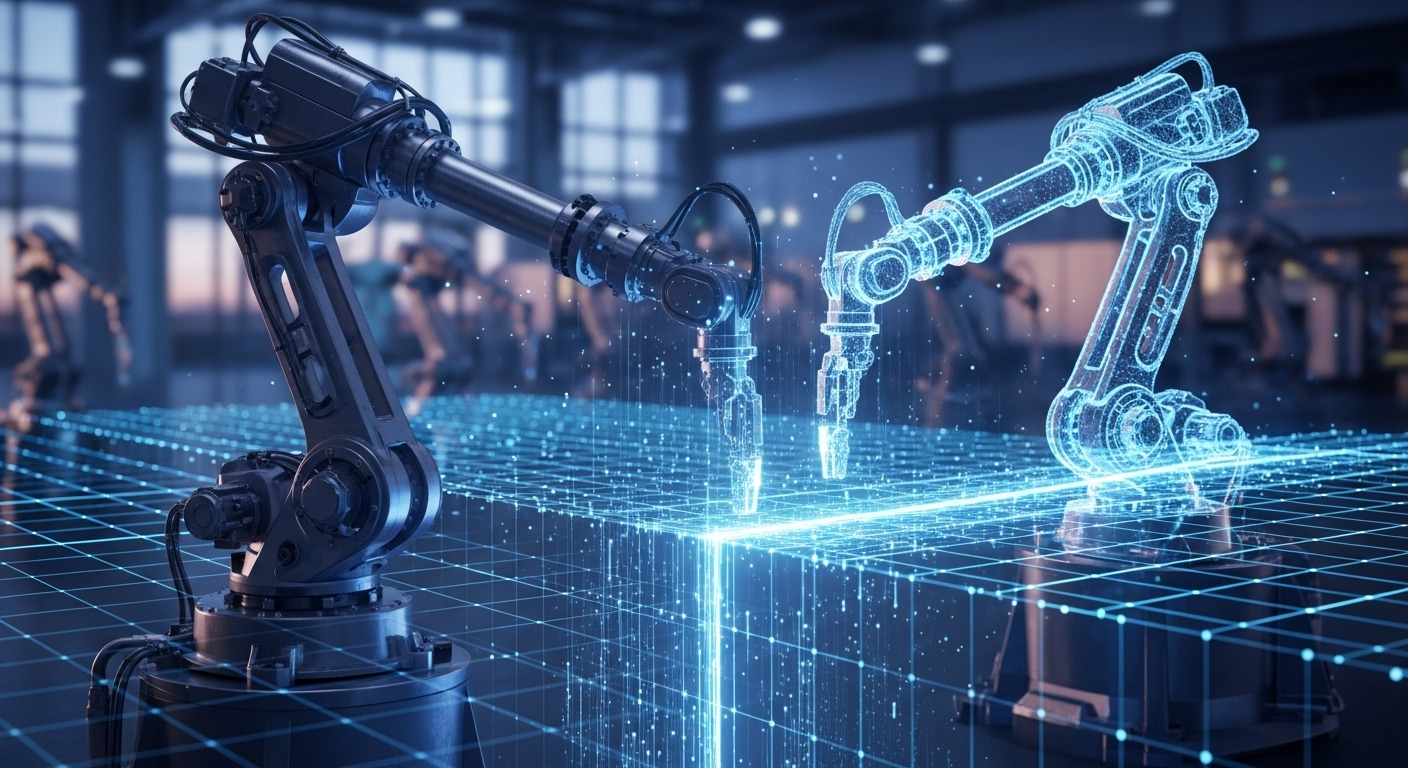

What role do digital twins play?

Digital twins create a virtual representation of an asset or system using live telemetry and engineering models, enabling simulation of wear, stress and repair scenarios without affecting production. By validating diagnostic hypotheses and estimating remaining useful life, digital twins refine maintenance decisions and reduce unnecessary part replacements. They also support remote diagnostics by providing technicians and engineers a shared view of machine state and likely fault progression. When paired with predictive algorithms, digital twins improve mean time to repair and contribute to more predictable equipment availability.

How does predictive maintenance affect supply chain and procurement?

Predictive maintenance produces forward-looking signals about likely part failures, helping procurement teams optimize inventory and supplier lead times. Forecasted consumption for spare parts enables just-in-time replenishment while avoiding emergency purchases that inflate costs and extend downtime. For the broader supply chain, higher and more predictable equipment availability reduces variability in output, improving coordination with suppliers and delivery schedules. Incorporating predictive outputs into procurement workflows supports resilience by aligning maintenance demand with supplier capacity and contractual terms.

How does it support sustainability and energy efficiency?

Well-maintained equipment typically runs closer to design specifications, which can lower energy consumption per unit produced. Predictive maintenance prevents the energy penalties associated with degraded components, frequent start-stop cycles, and inefficient operation caused by wear. Avoiding catastrophic failures reduces scrap and rework, which lowers material waste and the environmental impact of expedited logistics. Tracking asset performance over time also enables targeted interventions that balance uptime goals with broader sustainability and energy efficiency objectives across operations.

How do cybersecurity and resilience factor in?

Linking assets to networks for predictive monitoring increases the attack surface, so cybersecurity must be integrated into maintenance strategies. Measures such as network segmentation, strong device authentication, encrypted telemetry and secure update mechanisms protect predictive analytics and control systems from tampering. Selecting vendors with transparent security practices and incorporating redundancy reduces single points of failure. These safeguards maintain the integrity of predictive signals and ensure the resilience of systems that support equipment uptime rather than introducing new vulnerabilities.

Conclusion

Predictive maintenance extends equipment uptime by combining IoT telemetry, analytics, automation and digital twins to anticipate failures and enable targeted interventions. When those capabilities are integrated with procurement planning, energy efficiency efforts and robust cybersecurity, manufacturers gain improved production predictability, reduced waste and stronger supply chain resilience. Careful implementation and continuous tuning of models help translate sensor data into reliable uptime improvements across modern manufacturing operations.